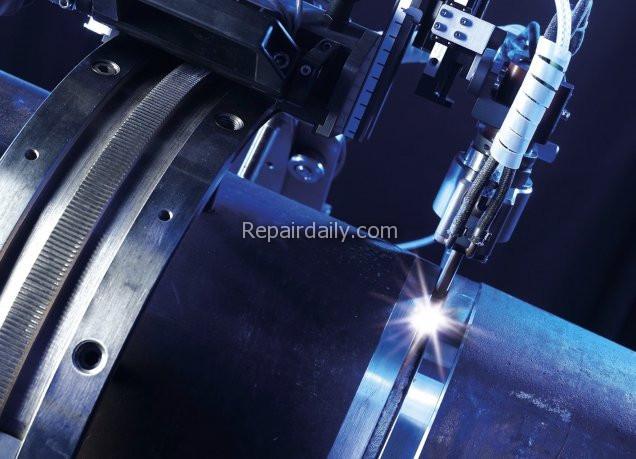

Welding is a fundamental process in many industries, including manufacturing, construction, and engineering. Welding has come a long way since its inception, and with advancements in technology, it has become more precise, efficient, and safe. One of the advanced techniques in welding is orbital tube welding, which is the automatic or mechanized version of gas tungsten arc welding used for welding circular objects such as tubes and pipes.

Orbital tube welding is a highly specialized welding process that offers a range of benefits that traditional welding techniques cannot match. One of the key advantages of orbital tube welding is its precision. This welding technique uses a specialized torch that travels around the circumference of the tube, maintaining a consistent distance and angle from the joint. This precision ensures that the bead profile is uniform throughout the weld, and the finished product is free of defects, such as porosity, undercuts, and excessive penetration.

Another advantage of orbital tube welding is its efficiency. Unlike traditional welding, where the welder must move the torch by hand, orbital tube welding uses a mechanized system that moves the torch automatically. This automation eliminates the need for an operator, which reduces the risk of human error and increases productivity. With orbital tube welding, a welder can complete multiple welds simultaneously, reducing downtime and increasing throughput.

Moreover, orbital tube welding can be done with or without filler wire, depending on the application. In cases where filler is required, the filler wire is fed into the weld pool automatically, ensuring consistent and accurate deposition.

Orbital tube welding has many applications in various industries, including aerospace, pharmaceuticals, food and beverage, and semiconductor manufacturing. These industries require precise and hygienic welding processes, and orbital tube welding meets their requirements. The precision and cleanliness of orbital tube welding make it ideal for industries that demand high-quality products and processes.

The American Welding Society Education Online Ore offers specialized courses and certifications in orbital tube welding. These courses provide hands-on training on the use of the equipment and the techniques involved in orbital tube welding. The certifications are recognized globally and demonstrate the welder's knowledge and expertise in orbital tube welding.

In conclusion, orbital tube welding is an advanced welding technique that offers precise and efficient welding results. Its automation and precision make it an excellent choice for various industries, including aerospace, pharmaceuticals, and food and beverage. Welders who want to specialize in orbital tube welding can benefit from taking courses offered by American Welding Society Education Online Ore. With this advanced welding technique, welders can produce high-quality products and meet the demands of today's industries.